|

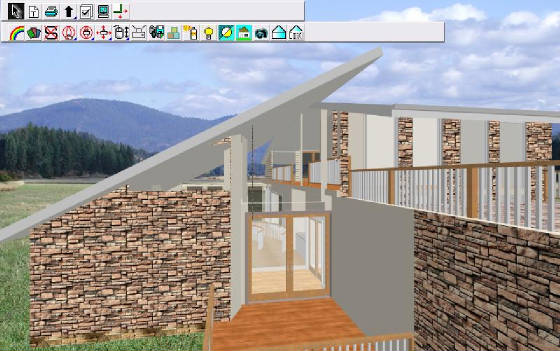

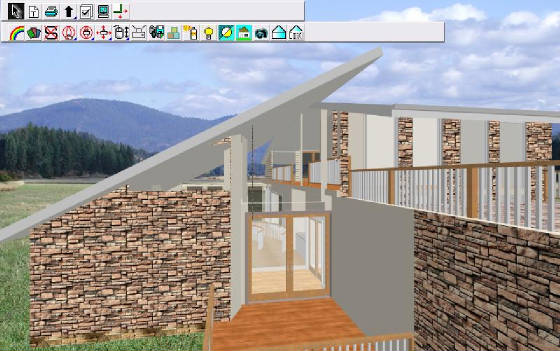

Ultra Contemporary, Spanish,

Ranch, Tuscany, Rustic, Victorian, really any style imaginable all with unbelivable Luxury carfree designer

finishes that would cost thousands more if site done luxury carefree finishes saving 10 to 20 subcontractors makes

buildings Affordable often for less than half of normal construction ) they

are quickly crane errected in exciting resort style homes of any style and finish. Abba-Fast Cast Co. use the revolutionary

composite concrete panel system licensed by TrussCast Co. made with Lava fiber ultra high strength self compacting

concrete and revolutionary poly cement foam fiber core concrete insulation as

sandwich core structural panels. AFC is a pre-caster of pre finished panels in

sizes 4 ft to 10 wide by 10 to 40 ft. long for container size international shipping of

complete buildings. The 8' by 8' to 10' by 20' ft ready to use designer

concrete kitchen, laundry, and bath utility modules manufactured to

international standards for building the fastest built millennial life

buildings of all types. The USA factory uses the proprietary high tec

modular utility core pre fab units to provide the fastest best quality construction

possible. The complete system can eliminate 10 to 20 sub trades by building the

Pre finished products cast in the fast

cast factory conditions, with wiring, plumbing, window, door framing and trim casing cast in

place with or without the glass glazing. Panels are cast with proprietary

TSV Mixing/Mold Casting machinery and proprietary molds as complete licensed factory

building systems for international factories. The 4 by 8 ft to 10 by 40

ft panels can be cast in just a few hours in lines over 600 ft long.

1 to 20 story buildings can be erected at the rate of up to ten

one thousand sq ft condos per day using the modular ready to use modular

cores. The fire and storm proof high style architecture is

available in designer luxury stone, tile, marble, granite, stucco, brick or any

patterned designs for building super green composite light weight all concrete buildings in any design

styles or sizes when building with

the fast Millennial Life affordable luxury composite panels that are

internationally shippable.

. that can be customized

with the optional Carpenter Stone new light weight concrete trim options. See Carpenterstone video

click on news (seeing is not believing)

Exciting pre cast open curved or straight concrete stairs with

optional open elevators.

Optional Unique or traditional style fire places with real

wood, gas or electric. Entertainment/fireplace centers are unique and affordable options.

Very open planning with optional sliding glass walls. and unique clear high strength thin cable balcony

and deck railings with metal bar style top railings.

Optional Interior design services

Dramatic Cantilevered Concrete super insulated roofs and balconies.

Optional infinity edge designer pools with large decks with open see thru cable and non corrossive

top bar railings.

Fast Cast can build any style from Ginger Bread Victorian, Spanish, Pueblo,Tuscany look or the most exciting and

best value Ultra Modern Beach Resort Styles.

Truss Cast Co. has the revolutionary mineral fiber (strong as carbon fiber )that bonds completely

to the concrete, in ultra high strength self compacting pre cast concrete made in pre finished panels in sizes of 4

ft by 8 ft to 10 by 40 ft. for container size international shipping. Also offering optional 8' by 8' to 8' by 20' ft ready

to use designer concrete kitchen, laundry, and bath utility modules manufactured for building the fastest

built millennial life buildings of all types. The optional proprietary high tec modular utility core pre fab units provide

the fastest best quality construction possible. The complete system can elimiate 15 to 20 sub trades by building the finished

product in the fast cast factory conditions with window and door framing and window framing and casing cast in place with

or with out the glass glazing. Panels are cast with TSV Casting machinery and magnetic steel Molds.

The 4 by 8 ft to 10 by 40 ft panels can be cast in just a few hours in lines over 600 ft long. Condos can be errected

at the rate of 10 one thousand sq ft condos per day using the modular ready to use modular cores. The Fire and

Storm proof high style architecture is available in designer luxury stone, tile, marble, granite, stucco, brick or any

patterned designs for building super green composite light weight concrete buildings in any design styles when building

with the fast Millennial Life affordable luxury composite panels that are internationally shipable. They are now

made in our factory or on site with portable batch plant and molds. We will soon have two new automated

factories now being built.

One in Arkansas and one in Texas in existing factory buildings with cranes. They are

being redone for our automated systems.

Texas plant has over 200,000 sq. ft of production area and several 100 acres available with all utilities

and roads already built.

They will use state of the art proprietary Ultra Lava Fiber Crete and Truss Cast Technology

and proprietary TSV Equipment and Molds by Global Museum Co. made at our 30,000 sq. ft. home office and International

Sales office with mold prodution space at 6100 West by North West Houston Texas 77040. The Proprieary Trusscast foam

concrete core truss panels and UltraLavaCrete has licensed TSV equipment Co. to build equipment and

molds for the factories that are now being licensed to manufacture the pre finished special fiber reinforced

foam core composite concrete light weight panels cast fast in a modern high production pre and post

stress concrete pre cast concrete panel factories that are now being contracted to be built around the world.

UltraLavafoam TrussCast concrete fiber foam core

panels have lavafiber and 10k. psi reinforced pre finished interior and out side layers 1/4 to

2 inch thick composite concrete with up to 8 inches of inslulated foam concrete sandwich filler making truss cores

with exotic pre finished surfaces of polished granite, marble, travertine, slate tile or stone like surface finished

structural architectrual panels that are strong as steel, fire and weather proof, non corrosive, lighter and

internationally shipable and will last for 1000 plus years. The optional blast resistant panels have extra woven lava mesh, and

lavafiber rebar reinforced for military grade blast resistant composite panels that are made of ultra

high strength 10 to 40 psi concrete with optional layer of lava cloth for reinforced bullet proof panels.

The M s panels also have the super foam fiber concrete truss core, It can also have

extra layers of epoxy woven Lava fiber or carbon mesh for additional blast and bullet protection. The optional

military grade light weight concrete bulletproof panels with foam fiber core ultra high strength concrete

that is lava fiber reinforced and bonded to light weight concrete foam core, or plastic honeycomb or

eps foam cores create the stress skin truss panels. The panels can have optional pre stressing or post stressing of the

lava rebar cables to allow spans of over 80 ft between structural beams and columns. This unique LavaCrete

Design concept can open up unique out of the box green LEED designs for maximum carbon credits when available.

The main advantage is the extremely fast building cycle can save millions on construction bonding and financing. The

unique long span ability allows for designs that are out of the box to give the architect and engineers

unbelievable tools. The inner and outer woven LavaFiber woven reinforcement has optional epoxy or UltraCrete

concrete cover to absorbs the majority of a blast or bullet force and continues to slow the fragments with the light

weight lava fiber foam concrete to be captured by the inner woven fiber bullet proof layer. The design span data of the Stress

Skin panels are truly amazing producing very long ductile spans when combined with new lava or steel pre stress cable

reinforcing similar to hollow core panels. The new panels are non corrosive and can be formulated with concrete strength

of up to 5,7,10, up to 30,000 psi. The structural pre stress panels can span up to 80 ft clear span with pre tension

designs.

This allows much more design flexiblity when wide open spaces such as parking garages or large meeting

rooms are designed with wide structural spans and design esthetics only made possible with of the unique green leed architecture exotic

pre finished polished stone like concrete piers or pilings, foundations , hollow site filled concrete beams, columns, and

the inslulated walls, floors, ceilings. and super insulated roofs that can be made to look like rough slate

or mirror polished stone finished composite reinforced concrete that would cost much more to produce at the building

site. The new formula UltraLavaFiber concrete can be made in strengths of 5,000 PSI to 30,000 psi. Concrete can be made

to be ductile for certain applications. The panels can come pre wired and pre plumbed with high tech fiber optics

or any data wiring and electrical systems. This modular factory production produces affordable storm and blast resistant buildings

that look like the most expensive granite or polished marble and glass architecture. The computer Lava Designs are cast in magnetic

panel molds that can produce thousands of parts very quickly. The mirror like molds are designed with state of the art

laser cutting, laser welding and powder coating methods to produce metal or composite fiberglass molds for casting any

panel shape or design that can be mass produced to reduce cost significantly. The Factories can produce and warehouse complete

shipable affordable luxury modular buildings very quickly with the modular high speed manufacturing technology that saves

labor and energy like no other system.

UltraLavaFiber Concrete and UltraLava Foam cement or Eps foam cores combine in stress skin truss

panels with concrete studs and joists to make amazing strong light weight airplane type sandwich box truss with

thin steel like inner and outher walls of armored woven LavaFiber designer Ultracrete for homes and high tech security

structures. There is a optional ultra Light weight panels made with Epoxy Lava Fiber Mesh that are also internationally

shippable in 8 ft (2.4 m) wide by 20 ft (6 m) or 40 ft. (12m) long. We also can produce USA shipable

10 ft wide panels that are ductile and non corrosive with the new lava rebar and lava weave fiber and fabric reinforcing.

|