|

This is a Private Draft Idea website only and no offers or proposals or offers to sell are intended with this information.

Technical Description of proprietary ideas,systems, formulas,designs of buildings,equipment,formulas, design and print copyrights,

Ideas that may or may not be patentable are part of the systems license to manufacture and build with a Royal contract for

the license rights. Many ideas are for information in draft form for research and development only and not statements of

facts. Garold Wormington and affiliated companies have used many of the methods and similar systems of building for nearly

30 plus years with improvements every year documented descriptions and plans by dated photos and dated agreements. TSVFabco

Trust is a Private Spendthrift Irrevocable Business Trust Co. that is now the endowed exclusive owner of all design and

systems etc. and license-or claiming proprietary rights to designs,formulas, methods, equipment designs,formulas, systems,building

and equipment designs, and print and design copyrights etc. to establish time basis for future patents butnow limited claim

of patents at this time. Warning this is a Private Draft Web Site for

viewing by invited viewers, bankers, and accredited investors only. All information

on formulas, designs, drawings, software, and systems, and uses are proprietary to Garold Wormington or his assigns

TSV Fabrication Trust Co. or Ultracrete International Trust Co. , or affiliated equipment manufacturers,

. Many of the systems and ideas may be patentable and he is establishing dated of use of ideas for future patents, but

he is not wanting to complete the patents to give competion too much info. He has several patents in the past but hasn't found

them profitable and very time consuming and very expensive. He pioneered dozens of patentable ideas that revolutionised

satelite home tv. years ago. Most of the break thru ideas for small satellite dish technology with quick delivery trailers

was his invention and he established largest satellite manufacturer and dealer business network years ago, but he found it

was better to beat the competion to market with ideas and product which he did and became the largest producer of satellite

dishes at that time. His designs of the various molds, prestress equipment, and mold and equipement manufactures have endowed

some of the the new ideas and proprietary systems for License to the licensees of TSV FabCo.Trust Co. the Global manufacturer

and value added marketer of the proprieary equipment designed or modified under license from UltraCrete Trust and TrussCast

Co., molds, proprietary formulas and systems that use 7 types of ultra light super strength cement

additives and Basalt lava fibers and Basalt Lava cloth that can be used to make bullet proof,fireproof 2600 degree melting

point of the Lava mineral fibers that bond completely to the cement matrix, along with tiny cell foam core cement or eps

foam cores, or Urethane Foam Core, or the super foamed concrete truss cores for the ultimate in Pre-cast concrete with light

weight fibers and micro particle aggregates, along with special silica fume formulas using special slag and micro Fly Ash.(ultracretesips

International Company., Lava Fibers Co.,Planatary Mixers Systems, and TrussCast Co. ( Private Companies .) along with Spancrete

Inc. and Voeller mixers inc., are the endowers to TSV FabCo which is the endowed Trust that will

be the license-or trust, which is now the owners, designers, inventors and builders and license-ors

of the equipment, molds, systems etc. Some of which is owned by other companies that have granted limited permission

to use their technology in exchange for using Wormington's technology, He has many systems and procedures that may be patented

but has decided not to waste the time and money now.

He has found that marketing the equipment and the actual products themselves is where the real money is. He is not marketing

the patents or ideas he is a license to formulas, methods, special molding technics and special auto mated batching equipment,

cement handling and special finishing and pre wiring, pre plumbing,Designs, copyrights and marketing systems that optimise

the use of fast erection of pre cast lightweight ore finshed panels that are super stong dense and when needed ductile concrete.

There are three types of factory systems he is marketing. The first is his pre finished methods of makeing architectural

wall panels and Truss floor panels that can be site cast in his molds using his portable batch plant designs, special designer

molds, cement handling and placing along with proprietary connections and errection methods. The Second systme also using

hollow core from Span Crete affilates when locally available for the longer spans or other hollow core manufactures when closer

to the construction site. They are marketing the Trusscast panels for the walls and some floor and roof systems and use some

conventional methods inside to finish the buildings. The stage 3 of plant development will be to build the complete modular

bath and kitchen cores in the factory in 8 ft.to 10 ft wide by 20 ft. up to 40 ft. long pre-wired, pre plumbed, pre finished,

pre air conditioned complete ready to set with crane and hook up utilities for the fasted move in possible.

unique there are several systems that use multi station factory assembly line building system that use unique slip

form precast high stack modular architectual foam core or hollowcore building systems that are using

his special additives and fiber formulas for low watercontent dry or additive flowable self consolidating concrete (SCC) Pre

cast, that uses large doses of ultra high strength bondable Lava fibers (mineral Basalt fireproof rebar, lava fibers,

and lava fabrics which are fully bonded structural fibers stonger than steel, kevlar, or as strong as carbon fibers.,)

and the revolutionary concept of 3d truss stress skin principles with ultra high strength concrete reinforced with 5

to 50 lbs. per cu. yd. of structural bondable fibers that totally reinforces ever sq. cm of concrete with thousands of fibers.

Composites are placed with special proprietary equipment manufactured by license to TSV FabCo a independent private company

and other affilates that manufacture equimpment, molds and proprietary additives. to Ultracrete Co. ,Trusscast Co., and

Lava Fibers Co. specifications. The engineering principles are similar to what is used in air

craft and boat construction. The amazing box ladder truss principle uses a foam web core as well as thin structural high

strength fiber reinforced joist and studs and beams that have special structural rated steel, fireproof mineral Basalt

Lava fibers, Lava Rebar and Lava woven reinforcements, as well as Duck Steel and PVA fibers in proprietary designed

additives for SCC and Dry blends.

When used in mid to high rise structures the structural panels also use proprietary steel or steel alloys

of reinforced and proprietary connection methods. rebar or Basalt rebar in special columns with pre and post

and pretensioned members to tie the modular sections and panels together. The buildings are completely pre

built 24-7-365 in a high tech state of the art assemble line factory that meet the international and PCI and Aci

Standards which are some of the highest building codes in the world. The perfected high style designer Trend

kitchen and baths are ready to use when crane set with all appliances, along with the designer finished wall, floor, and

designer roof panels that are built as international sized shipable light weight high strength

structural cores that are precision factory built with all the appliances, electrical, double wall plumbing

special cast in designer battery molds as modules that are 90 % to 95 % complete buildings made

in the factory on the ground level with the structural architectural panels that have very little steel or Lava

rebar in the panels. The ultra thin strong as steel stress skin designer pre finished exotic stone or stucco like

finishes on solid concrete with concrete foam cores produce light weight super strong panels that are manufacture

in insulated sizes from 4 ft. to 10 ft wide and 20 ft. to 40 ft. long panels that are designed to be

economically container shipped any where in the world by ship and then trucked to the site and set with a crane.

The new small portable factory home systems can be set up very quickly in exsiting pre cast factories or even

on job site by using our new TSV complete mobil automated batch plant and pre designed molding systems of TSV can be set

nearly any where.

The small panel systems can be designed to use very light errection equipment or even manual errection in some cases

by using the smaller Sip size panels.

We also have ultra light weight panels made in small 4 by 8 ft. panels and 2 by 20 ft concrete floor panels sticp

(structural truss insulated concrete panels) that are designed for homes and apartments that can be

erected with out the large cranes. This pre engineered system can be used in up to 4 story construction with very little

structural steel or post tensioning required. High Lava Fiber poured slabs can be 50 to 80 ft wide between expansion

joint lines. Some special super light weight panels are to be used in affordable trend style concrete

homes and condos built with Lava polished panels that can be erected with out crane assistance.

The thin amazing strong storm proof home panels come in 4 ft by 8 ft or 8 by 10 ft. wall prefinished designer concrete fiber

reinforced panels that can weigh as little as 200 lbs each on the non load bearing interior walls of 4 ft by 8 ft panels.

The 1 or 2 ft wide interlocking floor and roof panels can be up to 20 ft long and weight less than 300 lbs for manual erection

with special A frame lifts or small cherry picker type truck cranes. Special hollow columns can be used to stay

in place with the slick forms that can be made to look like expensive polished stone.

The pre finished column forms can be site filled with additional fiber concrete or rebar and traditional cement

with the lava fibers. With the column beam systems building can be made much taller. The proprietary small panel systems

also use the Ultra High Strength Lava fiber reinforced Ductile Pre Cast Concrete with special 3d High Density

Structural Fibers that have 10 times the ductile tensile strength and are mineral fibers that form true structural

bonding to create a structural reinforced Concrete Truss with the fire resistant, storm resistant, bug resistant homes are

truly multi century life long composite concrete buildings. The small panels are optionally exotic

finished and stained , polished or colored with Life Time designer stone or stucco finishes that are bonded

to the foam core and thin concrete studs and joist 1 to 4 ft on center depending on structure height. Unique architecture

details can be cast in the design and can be done with the special engineered pre finished concrete beams that

create a light weight concrete truss with thin concrete studs and joists and a dense foam core that provides a

continuous web member to transfer tension and compression forces that multiplies the strength by a huge factor.

The high style dramatic architecture designed by Wormington has several trend styles from rustic, Tuscan,

French, Spanish, Traditional to Ultra Modern styling with popular open concept floor plans with high 10 to 20 ft

even 30+ ceilings, with wide mansion size rooms, and lots of special solar assisted insulated glass opening to beautiful

spacious stone or exotic tile like stained concrete decks.

(The proprietary ultra strong but light weight

concrete is very dense and water proof due to

particle sizing and special minerals and fibers

that react chemically and bond structurally to the concrete. The proprietary plastisizers and water reducing

chemicals react with the high tech particle packing by control sizing creates a nearly unbelivable thin truss wall, floor,

and roof panels that are ultra stong and light weight for international low cost container afordable shippable on flat open

8 ft by

20 ft to 40 ft. long truckable containers.

Much of the strength comes from the particle compacting bonding with special fracing and fine round sands, silicas, and

minerals from our affiliated 5,000 acre Trinity River ranch development.

The storm proof concrete buildings use high strength alloy connectors to sustain hurricane force winds and water.

The engineered panel connectors (PCI specs) use special alloy reinforcing connecting methods, with Pre and Post Tensioning

Options on the high and mid-rise construction systems.

Much of the high tech proprietary concrete sytems and ideas are doucmented, dated as first use, and covered by 32 potential

pending issued patents by Wormington and his affiliated companies that are now assigned to TSV Fabrication Trust Company,

along with software, drawings and printing which is copy righted intellectual valuable property. All information

is proprietary to TSV Fabco Trust Co. and Ultracretesips International Trust Company, Garold Wormington, and the endowed

trusts for global licensing by TSV FabCo Trust Co. which is now the international licensor of the technology to their

licensees Dream Cast LLC. GlobeCast LLC. of Ghana using Span Crete Hollow core equipment, DesignCast Co. Of La. using

TSV Fabco Foam GreenCast Co. of Mississippi. Some companies and ideas are from years gone by and may not be accurate of current

systems being marketed. The Market has changed alot of the plans and proposed projects have been put on hold as banks have

demanded more and more equity to do projects talked about on this draft information website. Many of the proposed projects

are still viable when the market pick back up.

Scroll to bottom of page and

return to side menu.

TrussLavaCast Pre Cast is the strongest, fastest and most affordable building system available

The above planned projects offer Luxury Living in secure concrete buildings at affordable

prices

2 story Lofts will have exciting open 2 story views and dramatic sky lights.

Villas have optional unique open ventless gas

pre cast fireplaces

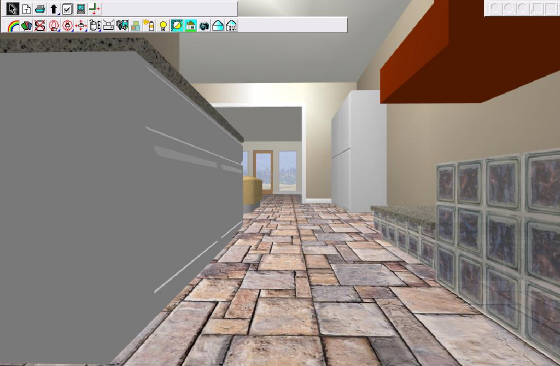

Luxury Modular Kitchens and Luxury baths built in 10 feet wide by 20 to 30 feet length and 10 feet high ceilings, with

fireplace rain shower spas in most units and super granite or designer concrete and stainless kitchens with

exotic wood cabinents with glass doors. The upper floors are 2 story Lofts up to 4600 Sq. Ft. All will have sliding

designer glass or wood doors on kithen and bath cabinets to allow wheelchair access under the sinks and kitchens (also wide

tall doors some with electric voice actuated ball bearing sliding doors, for handicap friendly living in high style

with out the handicap look.) Some will have designer glass atrium side or ceiling sky lights and aquarium divider walls

between bath and hall ways or kitchens to allow more light in to the rear and bedroom areas of the Villas. Some will

have loft balconies from bedrooms and halls off of the end and atrium units.

Optional Interior designers will do special Fire Place entertainment centers with special granite and and custom

Glass counter tops and stone, glass, copper and stainless accents cut with specail lasers used in custom kitchens,

baths, and art alcoves

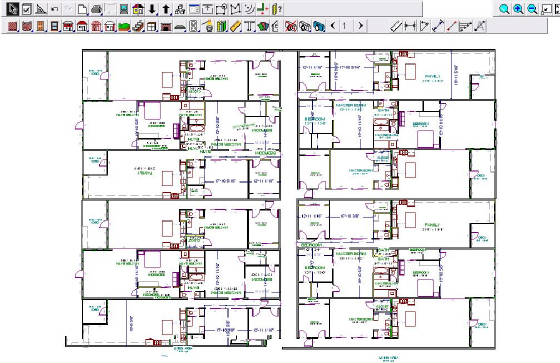

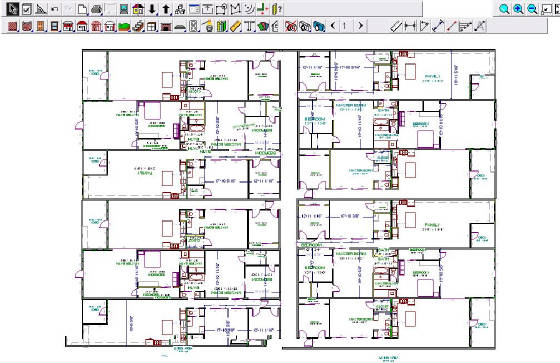

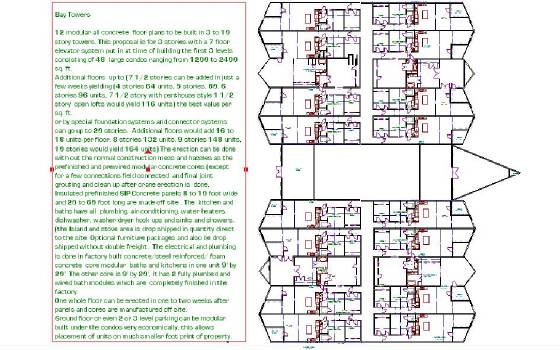

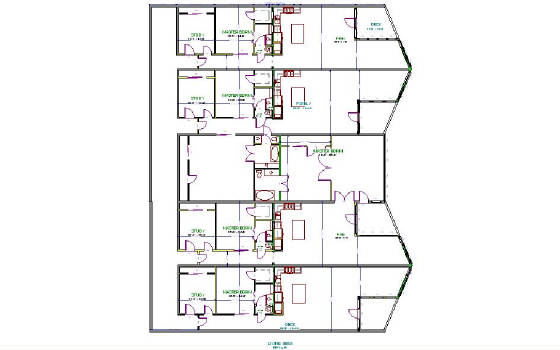

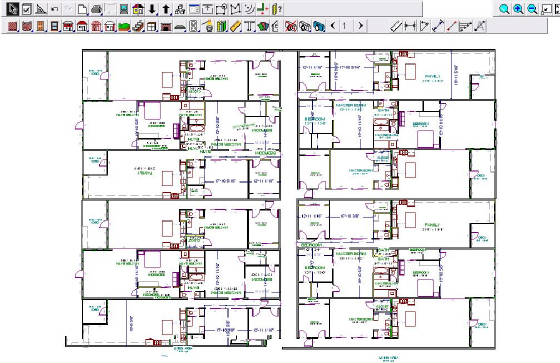

| Luxury Condo Plans 8 per tower per floor. |

|

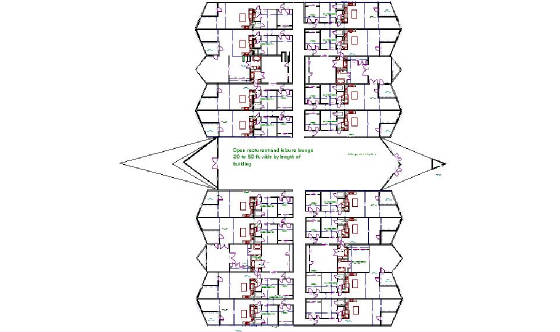

above is One Level of one Tower of Coastal Mansions' Twin conected Tower Plan. Towers can range from 4 to 10 stories

in theAffordable Mansion Series most have parking under building in the basement or part of first floor..

and up to 20 stories in the Penthouse metro series.

Pre-Construction Priced from $150,000 to $600,000 , metro series up to the millions depending on location, in the

mansion series some floors have four 2 bedroom 1500 Sq. Ft. and two 3 bedroom2 luxury baths 2200 Sq. Ft. and two

4 bedroom or

3 bedrom and media/game room and 2 luxury baths

of 2300 Sq. Ft.

The top floor can also have custom floor plans and will have guest suite bedroom and hugh office or media room

on 2nd Level giving 3200 to 4600 Sq. Ft. Penthouse Lofts.

The same shell structure can have 10 2 bedroom on some of the floor levels. This gives us many floor plan

options with out slowing factory production, there will be optional variations in the modular Luxury Kitchens

and Baths. All units have wide 36 inch door and designer cabinets with designer engraved, frosted or colored

sliding glass doors that are easy to pull up under counter with wheel chairs. The prices Quoted are factory Direct prices

exclusive of soft, land, freight, errection, and development costs.

Luxury factory built modular baths will have beautiful

water fall tubs with special glass illuminated glass block

and special aquarium sinks and rain spa shower divider

aquarium walls. Top floors will have 1 and 1/2 story units with lofts.

All units have unique energy saving glass walls and up units have unique sky lights.

The super energy saving E Tempered safety glass really opens the outdoor in.

All Units will have 10 feet by 20 feet stone patterned concrete decks. End units and attrium units will have 2

large decks.

With the unbelivable low prices for the size and unique architecture, The new buyers will have the money to do

optional exotic Interior design touches. We will have awards every month for the outstanding interior and Liquid Design

features indoors and out. The Garden Club will also give special awards monthly news letter recognition to outstanding

flower and organic salad gardens.

The flexibility of nearly 20 feet wide rooms with interior non load bearing walls and deck location options gives great

variety of plans.

Our prorietary unique designer concrete shell columns and beams and hollow arch beams (site filled with heavy rebar and

pumped concrete lets us build a totally sheer resistant building by adding the rebar and poured in place high strength

concrete to completely tie the precast panels together with the unique steel connections and the grouted and poured concrete

to tie the structure together from the deep pour concrete steel reinforced piers going down 3 to 40 feet depending on soil

and floor level loading, to the perimeter bond structural beams completely around each floor. This allows the building

designs to have unbelivable storm surge uplift and torsional strength from high winds of hurricane and tornado protection.

Also our unique pre-cast high strength e tempered glass or optional break resistant Lexan, is structurally bonded

to the lava fibers (Basalt Mineral based fibers) that are stronger than nylon, glass, graphite, carbon, pva, and

steel fibers that are used to reinforced concrete exterior which is cast in one piece 8 to 10 ft wide and up to

40 ft. long with life time concrete high density, fire proof, bug proof, storm proof, and waterproof.

The exotic designer finishes would cost 10 to 50 sq. ft extra to site finish by normal contracting sytems. The

polished finishes are slick as glass. The pre finished designer architectrual panels with life time exotic

finishes can have the special thermal and safety insulated glass windows and doors pre installed on the ground

before erections saving hundereds fo thousands on large apartment projects.

Thin shell structural Foundation Beams, Columns, molded structural arch beams and structural straight beams can

be prefinished with stone, slate, granite, brick modular block, coin designs or granite or limestone look. They are then site

filled with high strength concrete and Lava rebar or steel cages to completely tie each floor to the deep mounted reinforced

deep bell bottomed piers, and tie the floor panels together with reinforced perimeter bond beam. This allows erection of

next floor to go on immediately with out waiting for concrete to completely set and not having to wait on the forms to

be stripped. This can save millions on site masonry and stucco on large projects . Nearly 1.5 million on one Mississippi

project.

Luxury Villas can be customized by our interior designers.

Modular luxury baths have open fireplaces adjoing luxury spa tubs with multi head rain and hand held massage showers

with optional aquarium divide walls and glass sinks and sink

aquariums.

Plans for new factory to build

Precast Structural Concrete/foamcore/ Sip Panels as well as hollowcore with Luxury Modular Kitchen and Bath Cores

ready to use.

Plant is 220 feet wide by 500 feet long. Plant is capable of running 3 shifts a day 7 days a week and produce over $100,000,000

(One Hundred million dollars of luxury Villas per Year Per plant. See Sip Panel section for details.

Master plan calls for many factories in most major metro city areas. Houston Market alone is capable

of supporting

over 12 Empty Nester Tower Projects, (which is over $250,000,000 to over one billion )as projects market

and expand on 10 plus acre sites in suburban major Houston Area Country Club, Lake, or Beach View Projects.

Ultra Crete Sips Company plans to go pubic with factories as well as joint venture projects with other large Developers

and Contractors and go public with a Real Estate Investment Trust ("REIT") to own and manage many of the Mansion

Towers Projects active retirement -assisted-nursing-projects.

and assisted and nursing care facilities.

Warning this is a Private Web Site for viewing

by invited viewers, bankers, and accredited investors only. All information on formulas, designs,

drawings, software, and systems, and uses are proprietary to Garold Wormington owner designer, inventor and builder

of this unique slip form precast high stack - special formula concrete - foam core - steel reinforced modular

building systems. It also includes site poured tilt up building systems. The proprietary systems use

high strength concrete with special additives, (using special formula concrete), special reinforcing methods, connectors, and

erection systems. Much of the information is covered by 32 pending and issued patents, and all software, all drawings and

printing is copy righted intellectual valuable property. All information is proprietary to UltraLavaCrete SIPS International

Co. and Garold Wormington and their licensees Dream Cast LLC. , and Big Wheel Development.Inc. Contractor Developer (www.dream-catchershomes.com).

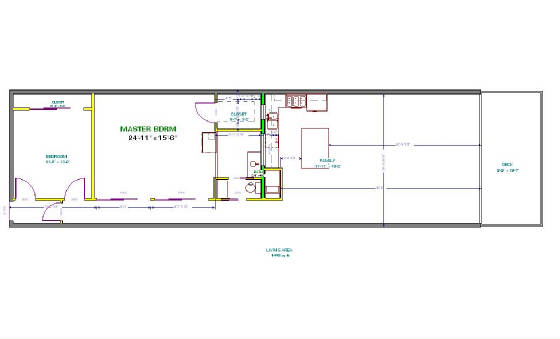

This starter floor plan 1200 to 1500 sq. ft. can have a huge 10 feet by 20 feet front deck (200 sq. ft. off of

the open family kitchen 30 foot by 20 foot wide (600 sq. ft.), or 40 by 20 feet (800 sq. ft. ) in the 1500 sq. ft. Villas'

family kitchen and 900 sq. to 1000 sq. ft in the larger 2200 to 3000 sq. ft. Villas ( plus 200 sq. ft. of

open living deck space bringing the out doors in for a total of 1200 sq. ft. of open living area, or half of the deck area

can be a 10 feet by 10 feet additional small light and airy office or den/guest room in the 1500 to 2300 sf. ft.

models. This smaller 1200 sq. ft. model in the Mansion Series has 2 large bedrooms and 1 1/2 bath with laundry

and walk-in closets. These are mansion proportion sized rooms and closets and baths so residents don't feel the cramped low

end apartment sized units of many luxury tower projects. Affordable space is made possible by the economies of

our large size panels and luxury factory produced kitchen/bath units for the ultmate in design, style, convience, luxury

and care free prestigious value with the low property taxes and no personal income taxes

in Texas.

Other models share similar family room and add separate Media/Game room/Guest Suite with additional large bedroom suite

and optional Large Media Room and fireplaces.

The 2200 sq. ft. and the 2500 sq. ft model, top floor pent houses are up to 3000 Sq.Ft. 2 story loft units that share

half of the other Luxury Bath Module Core (which is factory built with exotic granite and feature liquid design

aquarium sinks and open fireplaces with rain shower in luxury spa infinity edge water fall pool spas.) The stagered

floor plan separations share part of the 2 bath 10 feet by 20 feet modules with the opposite unit .

These Villas waste no space and have dramatic 10 ceilings, with high transom glass and skylights

on the penthouse top floors, all have and tall wide doors and all have handicap size baths and kitchens

( all units in the age 40 and older Mansion Villas that can be lived in thru retirement and have access to assisted

living if and when needed. All have handicap capable layout with special sliding doors on the cabinets that can be wheel

chair accessable and are all handicap friendly with out the stark look normally associated with handicaped accessable units.

The some of the luxury end units have side balconies from the bedroom and media room, in addition to the spacious front

deck off the main family kitchen core which is part of the 1/3 bath with fireplace and open rain shower spa wheel chair accessable

area. Some of the units overlooking the high liquid design atrium with ceilings up to 20 stories high or what ever the building

height also have inside deck over looking the resturant and piano bar lobby below.

This Luxury Bath core has on 1/2 bath off of the Hall or accessable from the second Large Master/Guest Suite

bedroom with optional fireplace. the other half of the10 foot by 20 bath core is share by the other adjoining unit on

the right.

end units and court yard atrium units will have exciting cantilevered balconies from master bedrooms

Basic 1200 Sq. Ft. 2 bedroom 1/13 bath with large deck 1400 sq. ft. with spacious out door deck with

optional pull down screen.

Starter unit running from 1200 sq. ft. to 1500 sq. ft. and Prices starting in some projects from $150,000 With Garage

Parking plus Interior Designer options which can run the price up considerably.

We can build most exciting architectural styles, using your architect and engineers or ours. We

have the fastest and best systems using the longest life and the strongest precast insulated high

fiber reinforced concrete (structural insulated panelized) SIPS. This is

a revolutionary cost saving worry free building and (foundation system using deep precast formed concrete shells)

that are site filled with structural high strength hybred fume concrete and rebar tied into the drilled and site poured concrete

steel reinforced deep piers). This pre-formed concrete forming shell allows optional bell bottom pier system which becomes

a continuous monolithic designer decorated concrete steel reinforced pier down to bed rock or to engineered

strength compaction. We also use a unique high strength water proof composite fiber piling stem when needed. This unique proprietary

system saves tens to hundreds of thousands on foundation and site fill preparations. The PCI and ACI certified

precast building methods reinforced with super ductal fibers and when need heavy structural steel, Our

system does not use Light Gauge Steel or wood/OSB as some Sips use. Highest possible sound and fire ratings

alon with lowest insurance rates. The engineered proprietary treated steel conection system has made economical

construction available in towers to 20 stories and even to 50 stories above with modified Post tensioned designs and engineering. The

precast designer piers allow us to place economical secure elevator accessable or

valet parking garages on the lower floors and lift the Villas

all living areas are above the storm surge on beach front properties. This system can be used for any commercial, industrial

and residential buildings. Our ultimate cost to value is in residential and office,

mid and high rise construction using our one of a kind factory pre-built structural lighter weight concrete

panels and Luxury Granite and Kitchen and Bath Precast composite fiber concrete cores allow us to build

the modules while or before the site development and foundation is

being built. The interest savings is amazing and the much quicker occupancy make the project much more profitable.

We will do joint ventures or any phase of sub contracting. We are licensed and bondable to do very large projects. Our

special proprietary designs and sytems will be available in many metro markets very soon as we are expanding plant operations

to many states thru joint ventures and our soon public stock offering. One or more of our plants will be on the ship channel

allowing us to ecomomically barge ship prefinished luxury concrete structures for 1000's of miles with low cost water

or rail or truck freight.

This great revolutionary system gives superior security, low maintainance, storm, insect, mold, flood

and fire protection, and 100's of years of structural life. The new villas for (age 40- and over empty nester)

known as Coastal Mansions Projects will be built in 3 to 10 story luxury penthouse towers that

have dramatic spacious indoor-outdoor resort living areas

with mansion sized rooms and open dramatic cantilevered decks. Some will have prow or rounded shaped light

filled living space with large concrete flagstone decks. The Towers will have dramatic lighting and unique architecture.

The Villas have tall 10 foot high ceilings, tall door opening and a full walls of designer safe tempered

storm and noise reduction E glass sealed with structural silicon to graphite-carbon fiber concrete designer window and

door frames forming glass walls nearly 4 to 6 inches thick with dual storm resistance. The exterior doors are

of special concrete with

fiber graphite-carbon reinforced with 2 layers of tempered E glass in doors with over 1 and 1/2 inch

of space between glass for an insulation value of nearly 4 instead of less than 1 in most glass doors. The energy saving

glazing system allows us to build energy effient large glass walls with high transom tempered safety glass which gives a

very bright exciting resort feel. The large glass insulated walls bring the beautiful outdoors inside.

Many rooms have huge carefree concrete flagstone decks canelivered from all sides of the towers. The towers

can be very dramatic overlooking Lakes, Beach, Pines, Oaks, and Palm trees. Our new Villa Tower condo projects

will have water featured liquid design atriums and up to 10 story port o cochere entrances with first floor

under building secure garage parking, (Valet service available ) and Private by police or court order only triple

video and remote gate guarded security.

The spacious liquid design open atrium soar to the top floor with dramatic sky lights and interior cantelivered

interior and exterior designer concrete decks. The manicured landscaped

grounds will also have many lakes, and water fall liquid designs in tropical palm settings over looking golf style

liquid design water flower scaped landscaping. Which will have several pitch and putt greens, tennis, croquet, badminton,

ping pong, all types of excercise equipment. The club houses and

excercise spas will have state of the art fun excercise and aerobic water excercise spas for the anti-aging

wellness lifestyle. The age 40 and over empty nester concept

with affiliated nearby assisted living is close by in another part of the project so the residents don't have to worry

where they will go if the need assistance or nursing care later in life. The Conroe and Woodland hospitals

are just minutes away. The secure luxury high security buildings and gate guarded

grounds lets you enjoy your friends and leisure during retirement with real worry free peace of mind.

Your family will sleep in peace with the security of being free of storm and burglar worries in the

mood uplifting designer styled, reinforced bullet proof, fire proof, termites free villas and patio homes. Live

worry free in quiet environmentally, mold safe, beautiful low energy buildings, ( save 40 to 70 % on utilities and

the lowest taxes in the area. (also no personal income tax in Texas). We also will have on site banking and special

trust management programs.

There will be a private club piano lounges and many cafes and resturants on the scenic lake view roof tops and

open atrium lounge areas. The free state of the art equipment will be for

the private club members and their guest. There will also be a

optional wellness spa and beauty shops on site.

Only Ultra Cretes Sips offer super insulated and optional radiant barrier concrete panels 4 feet to 12 feet wide

by 10 feet to 60 feet long. We do regular smooth finish stucco look or imprinted stone, brick, tile, and slate

patterns or any site applied brick and stone options. The super insulated radiant barrier concrete tile look roofing

system is beautiful as well as super energy efficient with R 40 + rating. The revolutionary rotary split

heat pumps with long life and high Seer ratings are quieter and operate much more effieciently by not having

the environmental safe duct system in hot attic areas. Research is now going on to do integreated Solar panels using

the revolutionary 6 to10 times more efficient thin film technology for the ultamate in low energy or up to 100% site generated

power for the strucure and additional power to be sold to the grid. The Ultra Green Building sytem with integrated cooling

of the solar panels make them much more cost effective and many times more efficient. First Solar is allready mass producing

the thin film technology. The homes and condos will also offer solar heated water and floor radiant heating molded into the

floor and ceiling panels for the ultimate in quiet low cost heating and cooling. The pre-finshed pre-wired and pre-plumbed

systems allows our system to be very cost effective and still provide the very best fast building system ever. We also have

a revolutionary affordable " Deep Concrete Pier and Beam foundation system or the basement or crawl space concrete foundation

system. The new modular designs offer very unique dramatic architectural styling with cantilevered decks

inspired by Frank Loyd Wright. Live the

American Dream Life Style in affordable designer style buildings built in record time at affordable prices,

often costing less than conventional construction. Compare every thing out there and nothing comes close to our systems.

10 feet wide by 20 feet long, Luxury bath module shared by the by the left and right unit adjoing the 20' by 80'

central shared unit. It has private stool areas and Luxury Rain Shower Infinity edge water fall Spa Tub with open see

thru fireplace. Granite or luxury Designer Concrete and Glass Aquarium options under sink or on infinity edge of

Spa tub. These are feature normally only found in Million Dollar Penthouses. The top floors penthouses will

have two story 20 foot high open ceilings to large Loft Game Room Bedroom Suites over looking the Lakes and Golf Style Liquid

Design Landscaping.

Live the American Dream of the Penthouse Life Style in mansion size rooms at affordable

prices. This Luxury Tower Concept is taking the country by storm, get in on the ground floor investments now.

Reserve yours now. Many speculators will be buying just for investment.

Our total designing and building systems is unique to our company. Many companies offer some

precast or tilt up

systems but most still have to be finished by hand in the old traditional time consuming costly

ways. And all the real time consuming operations such as insulating, electrical, plumbing, and airconditioning, installing

brick, tile, stone, , dry wall, cabinets, counter top, electrical and plumbing and air conditioning trim out, molding

trim, doors, windows etc are all very time consuming especially as most trades have to be done at different times in

a multi level building. The over all cost and construction time is typically in the 10 to 24 month project scheduling, (due much to weather delay)

and the fact that most operations have to be completed before the rest can be done.

Also material theft and damage from trying to house and move all the materials

up stair ways or crane during the process is very expensive. The old out of date methods of on site construction

scheduling is no longer affordable and the resulting buildings are very inferior to ours, due to the fact that doing

things up in the air is not nearly as fast as factory conditions. The shell erection and finishing can not happen until

other events happen, We are able to shave months off of the construction schedule by pre-building in the factory all

the real time consuming operations off site while the clearing and pre landscaping, permitting, under building utlilities,

parking foundations and utilities are going in.

We can build much better quality luxury granite kitchens and baths that, that would cost

1000's more if built on site, they also have 90 % of the wiring plumbing and air conditioning ready to go when

set by crane. Building in factory controlled conditions gives a much lower overall price with out he normal

damages that happen from lugging every thing up 2 to 10 flights of stairs. There are very few companies that even offer

prefinished panels. None I know of that do our total designed and pre-engineered and pre built modular concrete core

kitchens baths and closets.

Modular pre-finished foam core panels can save millions

or dollars in material and time saved to build the best class of all reinforced concrete towers and home construction.

We also build some commercial project with regular unfinished hollow core panels for spans

up to 60' between beams including parking garages..

click here for www.lavacretedesigns.com

click her for Big Wheel Development, Inc. Jimmie D. Wheeler Contractor and builder of Towers

|